Recently, a number of media reported that BASF, the world’s largest chemical company, plans to reduce its production in Germany and move production to China. Dr. Jianfeng Lou, Chairman and President of BASF Greater China, said in an interview that it is the logic of BASF’s development in China to turn the concept of sustainability into products at your fingertips and leverage the green value chain.

1. Major adjustment: BASF closed 11 factories in Germany

To date, BASF has closed 11 production plants in Germany. As the economic situation remains fragile, BASF’s austerity program in Germany will increase by 1 billion euros, which is likely to result in further layoffs and production stoppages.

It is understood that a number of media outlets reported that the problem is mainly in Germany: high energy costs, high bureaucracy, and excessive regulation (including aggressive carbon reduction policies) have led to no profit margins for chemical companies like BASF. In Ludwigshafen, 11 production plants will be closed, including a once-leading, modern TDI foam production facility, which is no longer profitable and has an estimated cumulative loss of up to 1 billion euros.

2. BASF continues to increase its weight in China

At the same time, according to the German chemical industry association VCI, 20% of investment in the German chemical and pharmaceutical industry recently went to China. BASF is thriving at its large-scale plant in Nanjing, China, and is investing 10 billion euros in a new gigafactory in Zhanjiang.

In Deguan plant, but in China increased investment. BASF’s choice was not accidental. With its huge market demand, complete industrial chain support, and relatively low production costs, China has become an ideal investment destination for global chemical companies. As BASF foresees, “China is the world’s largest chemical market” and “by 2030, China will account for nearly three-quarters of global chemical production growth”. In BASF’s view, China’s growth model is shifting towards high quality and sustainability.

According to the BASF Greater China Annual Report 2023, BASF has invested more than 10 billion euros in Greater China to date, co-invested nearly 14 billion euros with partners, and has 30 production sites in Greater China.

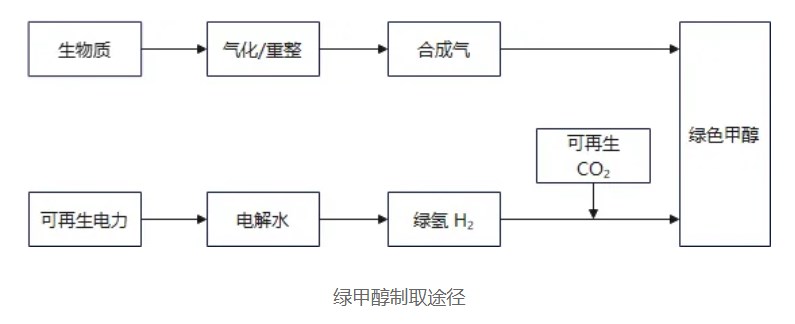

3. Two major contracts for plastic recycling and regeneration have been signed to deepen sustainable projects

“BASF has set itself a goal of achieving net-zero CO2 emissions globally by 2050. In 2023, we will also incorporate our Scope 3.1 targets into our latest climate protection targets, in addition to Scope 1 and Scope 2. To achieve this ambitious vision, it is necessary to carry out coordinated carbon reduction in both upstream and downstream. That’s why BASF’s decarbonization journey includes sourcing responsibly, producing efficiently and safely, and providing sustainable solutions across the value chain and its own operations. Dr. Lou said that BASF has developed a digital solution that can be used to calculate the “cradle-to-gate” carbon footprint of its 45,000 products on sale, and can openly share the calculation method of its product carbon footprint with suppliers, customers and peers.

01. BASF, DOMO and other chemical giants have formed an alliance to support the recyclability of polyamide film packaging