FORVIA, the world’s seventh-largest automotive technology supplier, made its debut at CHINAPLAS and joined its subsidiary MATERI’ACT, a company dedicated to the development and production of sustainable materials, to uphold the concept of “energy saving, emission reduction, and carbon neutrality”, and to promote green “new quality productivity” and actively shape a sustainable future.

Open up a new track and lay out the future industry

It is reported that in 2022, Faurecia and Hella merged to form Freya Group, of which Faurecia focuses on four business divisions, namely automotive seats, automotive interiors, Clarion automotive electronics, and green mobility. In order to realize the Group’s corporate vision of achieving carbon neutrality by 2045 and its sustainability strategy, MindRay was established in November of the same year to develop new materials that reduce CO2 emissions by 85% compared to existing materials.

“Majirui will meet the needs of global automakers working on projects in China, as well as the diverse needs of local automakers, including plans to add more sustainable components to their vehicles to enhance competitiveness and provide high added value to their customers,” said Jin Mingqi, R&D Director of Faurecia’s Automotive Interiors Division in China. Through CHINAPLAS, we hope to show you the cutting-edge technology products in the field of materials, especially in the field of sustainable materials, including plastic particles and various new technologies on sustainable skins, to bring innovation in sustainable solutions to the Chinese market.”

Create new advantages and accelerate green development

MindRay brought a lot of cutting-edge technologies and new materials to the industry, such as:

Modified materials

Plastic Odyssey door panels, debuting in Asia, are made from Ocean Bound Plastics (OBP) and are a collaboration between the FORVIA Foundation, Megary and Plastic Odyssey. Instead of black, the petroleum-based material is made of Plastic Odyssey material collected from the beach and oyster shells. The combination of ocean plastic and biomass reduces CO2 emissions by 20%, paving the way for Maggira to achieve its goal of reducing CO2 emissions by up to 85%. This panel showcases the ability of FORVIA and Magirui to use up to 20% ocean plastic in the production of compounds for high-performance applications, and highlights the ability to integrate recycled plastics into existing automotive interiors without compromising the stringent standards set by automakers in terms of performance and safety, or the quality consumers expect.

IniCycled is a sustainable compound that can be used in visible or non-visible parts with 20%-80% recycled content. Through the advanced lightweight injection molding process, IniCycled can achieve high-quality surface decoration. It can meet the requirements of demanding car manufacturers in terms of processing and color.

NAFILean-R consists of 20% natural hemp fibers combined with a 100% recycled polypropylene matrix. It brings together the best of both worlds, renewable fibers, which reduce CO2 and improve mechanical properties, and the integration of recycled materials, which enable a circular economy with a very low CO2 footprint. Compared to other industry standards, the material not only reduces weight, but also reduces CO2 emissions by up to 87%.

NAFILean Vision is a composite material developed specifically for exterior decoration requirements. It offers a great deal of design freedom. It can integrate a variety of biomaterials (hemp, wood, reeds, olive pits or oyster shells), as well as recycled plastics from multiple sources, from post-industrial and post-consumer plastics to end-of-life cars and ocean plastics. NAFILean Vision is fully recyclable and is available in a variety of shades and textures to create a premium decorative effect.

Leather fabric

Thermoplastic polyolefin (TPO) is a low-CO2 emitting surface coating (skin) that can be used as an alternative to leather and polyvinyl chloride (PVC).

Piñatex Advanced offers a high-end alternative to leather. It uses recycled pineapple fibre as a surface coating and is made from up to 60% renewable materials, reducing CO2 emissions by 90% and reducing weight by 25%.

Win the new schedule and empower a green life

Megaric currently has three product lines, namely plastic pellets (granulation), sustainable recycled skins, and recyclable carbon fiber materials.

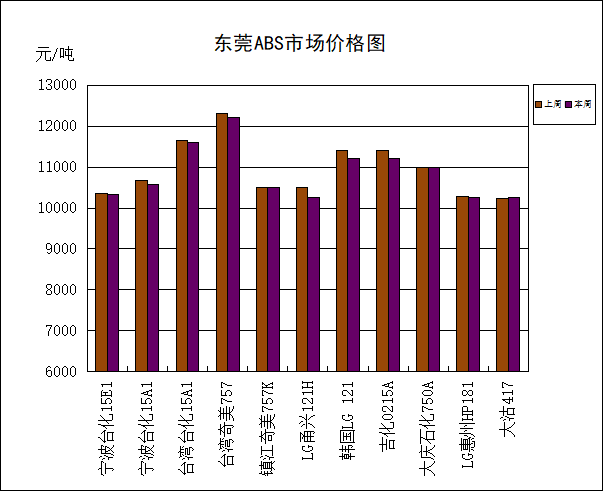

1. Plastic particles (granulation) have launched three different materials, the first NAFILean material, which makes biological fibers such as hemp fiber into particles to achieve the appearance effect and carbon emission reduction materials, which replaces the unsustainable and non-recyclable PC, ABS and PP materials with glass fiber. The second nicycled P is to make recyclable materials into PP raw materials, so that it can reduce carbon emissions by 20%-85%. The third ABS is the recyclable ABS.

2. For the epidermis, there are also three different epidermis, the first is the collection of leaves from the pineapple leaf production area, and the fibers of the pineapple leaves are reused into the epidermis. The second is to break up a lot of TPU materials to recreate the skin, which is a process of recreating the skin, which can be done similar to the interior or seat. The third is to combine the particles of hemp fiber and the fiber PVC of hemp fiber to make the back of the epidermis, that is, the front skin is PVC, and the back is a soft fabric with hemp fiber.

3. Recyclable carbon fiber is currently in the research and development stage, carbon fiber as a cutting-edge technology, and the follow-up specific product lines and product applications will be revealed to the public in the near future.

Green carbon reduction development and scientific and technological innovation development is the only way for enterprises to achieve sustainable development, and only by continuously cultivating products with innovative thinking and becoming more refined and stronger, can we achieve the same frequency resonance of scientific research achievements and independent innovation. With the concept of carbon reduction and sustainable development, Freya Group will continue to develop new quality productivity, drive a new engine for green and energy-saving development with innovative thinking, and continuously empower innovation in the field of sustainable materials with high-quality independent innovation vitality!